FLUXOFIL 54 is a seamless copper coated basic flux cored wire for hardfacing deposits having high wear resistance, such as excavator parts and bearing surfaces.

- Due to the low carbon content, the weld metal is very tough and therefore particularly resistant to heavy shock and impact. Machining by chip-forming is possible using carbide-tipped or hard metal cutting tools.

- A buffer layer, using FLUXOFIL 31, is only required in case of difficult-to-weld steels. When hardfacing unalloyed base metal, maximum hardness of the deposit is obtained in the first layer.

- Before depositing the final layer in multi-layer welds, the interpass temperature should not exceed 250 °C.

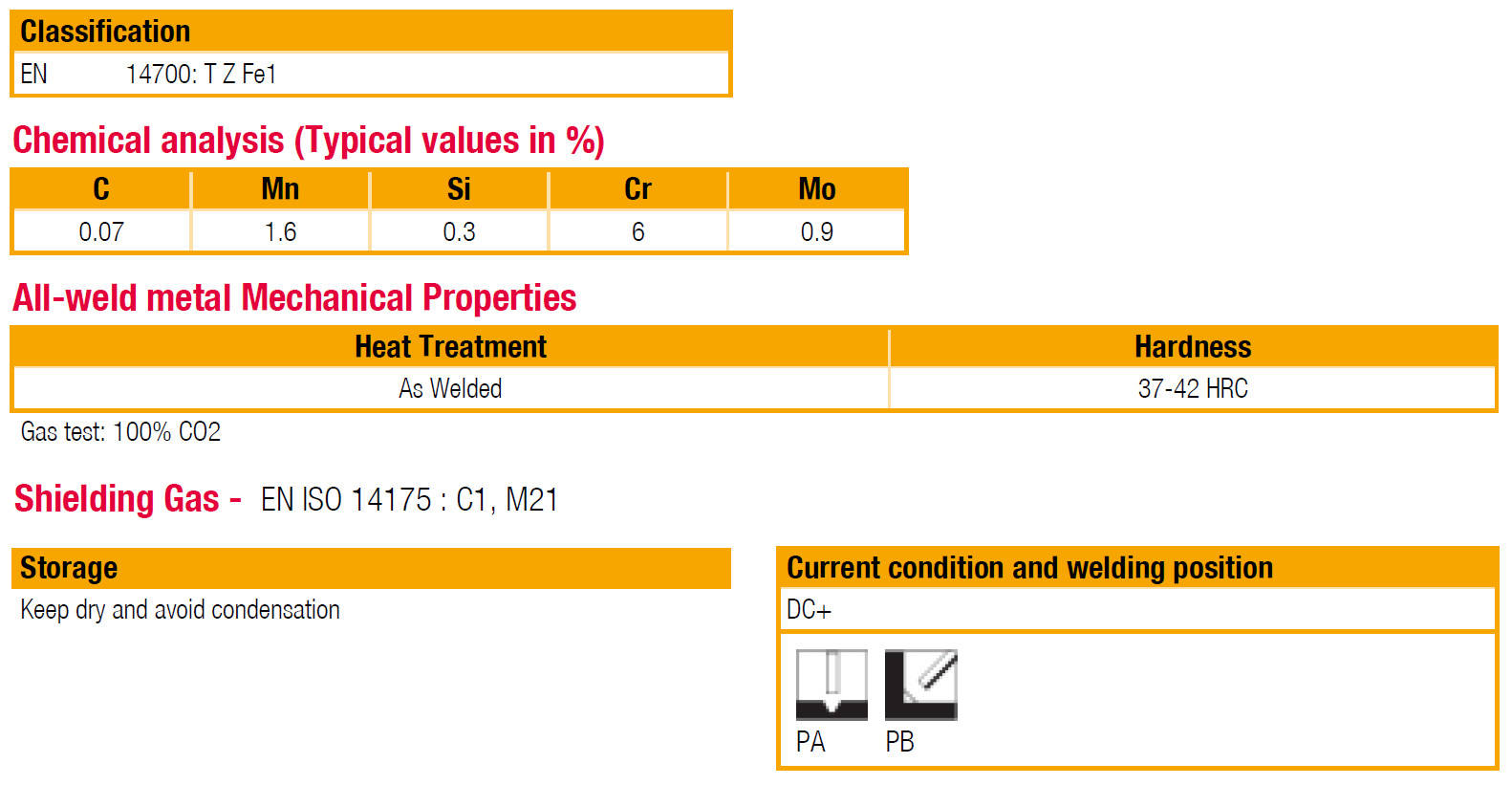

EN 14700: T Fe8

Tech specs:

| Wire diameter: | Ø 1.6 |

Users reviews