The Ideal Expert TIG 220 AC/DC PULSE LCD is a portable power source built on IGBT technology. It enables welding using TIG, TIG PULSE with both alternating current (AC) and direct current (DC), as well as MMA welding with direct current (DC). Due to its compact size and weight, the welder is well-suited for both workshop and field applications. It allows for welding at 155 A with a 100% duty cycle and at 200 A with a 60% duty cycle. The machine is constructed to protection class IP23. The welder weighs 13 kg and its dimensions are 530 x 195 x 370 mm.

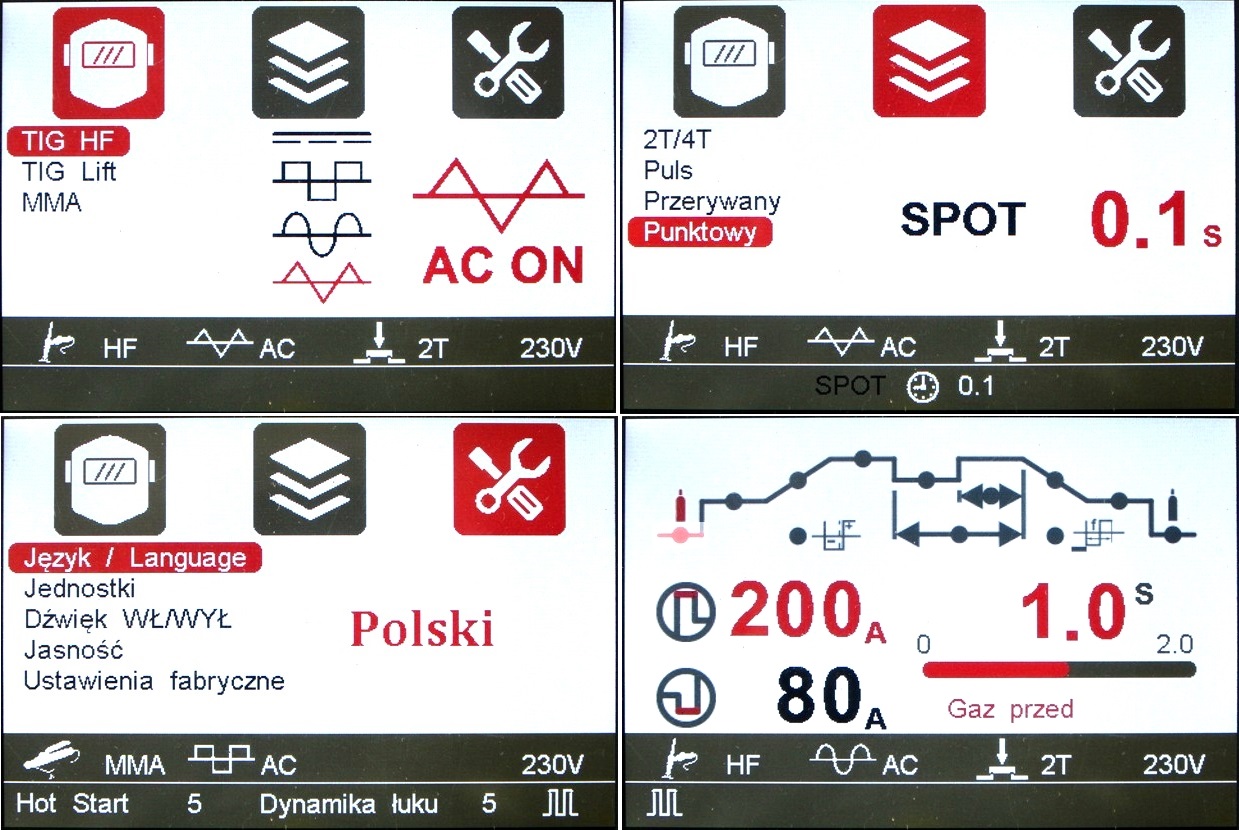

The device supports the following welding modes: TIG DC, TIG DC PULSE, TIG AC, TIG AC PULSE, TIG SPOT, TIG 2-LEVEL, MMA AC, MMA DC, MMA PULSE.

TIG DC and TIG DC PULSE modes are used for welding stainless steel, carbon and low-alloy steels, copper, and titanium. TIG AC and TIG AC PULSE modes are used for welding aluminum and its alloys, as well as brass.

TIG SPOT function is used for tack welding thin materials.

The TIG 2-LEVEL function (2-level current adjustment) allows switching between a higher and lower current level by pressing a button on the welding torch without interrupting the welding process. This feature is useful for continuous seams on materials of varying thickness and when there is a need to increase or decrease the welding current without extinguishing the arc. It is also beneficial, for instance, when welding aluminum for better control of the material’s temperature.

The TIG PULSE function allows users to adjust the shape of the weld and the focus of the arc. Pulsed welding reduces the amount of heat delivered to the material and is particularly useful for welding thin materials.

The welder allows for arc ignition in both contactless mode (HF) and contact mode (LIFT). Contactless mode is used in environments with a high risk of electromagnetic interference.

In both ignition modes, users can choose between 2-tact and 4-tact operation (the latter is used for longer welds).

The welder features a clear and user-friendly control panel that allows for precise adjustment of the device and ensures stable parameters and high-quality welding. Additionally, it includes a JOB function that provides 9 memory slots for storing user welding programs.

The LCD display allows adjustment of parameters such as: initial shielding gas flow, initial current, current rise time, welding current, base current, current fall time, final current, final shielding gas flow, pulse length, pulse frequency, interrupted welding length, HOT START, ARC FORCE.

From the control panel, you can choose between triangular, rectangular, and sinusoidal AC voltage waveforms. When welding using the MMA method, the user can perform pulsed welding and adjust parameters such as base current, pulse frequency, and pulse width.

The welder also has a range of advantages and functions such as:

IGBT - the device uses modern transistors that ensure minimal electromagnetic interference and low power losses. They also enhance performance and extend the reliability of the welder.

2T/4T - the two-stroke mode is best suited for shorter welds, while the four-stroke mode is used for longer welds.

HF IGNITION - contactless arc ignition, with control of the welding torch via a button.

PULSE - a function that improves control over the welding process and the quality of the weld. It is particularly useful in forced positions. It reduces spatter and provides less heat impact, which is very beneficial for thinner materials as well as those with high thermal conductivity, such as aluminum alloys.

PRE GAS and POST GAS - functions useful for shielding the weld pool, which may suffer from oxidation without additional gas shielding.

HOT START (hot start adjustment) - a function that facilitates electrode ignition by supplying higher welding current for each arc start.

ANTI-STICK (anti-stick function) - automatic deactivation of the welding voltage if the electrode sticks to the workpiece, making it easier to detach and preventing accidental arc formation.

ARC FORCE (arc force adjustment) - facilitates the transfer of molten electrode droplets to the workpiece, preventing the arc from extinguishing when a droplet touches the weld pool.

FAN STOP - a function where the fan speed increases at the start of the device and when it heats up, and decreases when the welder is cooled down.

The Ideal Expert TIG 220 AC/DC LCD welder is equipped with a TIG SR 26 torch, 4 meters in length.

The device can be connected to wireless remote control and also a remote control pedal, which help control the welding current and facilitate the operation of the welding equipment.

The welder is powered from a single-phase 230 V network using a standard power plug. The device comes with a 12-month warranty for professional use. The warranty service is provided door-to-door without transport costs for the customer.

The set includes:

- IdealExpert TIG 220 DC PULSE LCD welder

- TIG 26 torch with remote control (4m)

- MMA electrode cable (3m)

- Ground cable (3m)

- User manual

| Main power supply: | 230 V, 50-60Hz, 1ph |

| Maximum current: | 220 A |

| Duty cycle 100%: | 155 A |

| Duty cycle 60%: | 200 A |

| Degree of protection: | IP 23 |

| Dimensions: | 530 x 195 x 370 mm |

| Weight: | 13 kg |