The Speedtec 400SP by Lincoln Electric is a third-generation multiprocess inverter power source, excellently suited for numerous applications in industry. Its dimensions are 550 mm x 295 mm x 625 mm, and it weighs 53.5 kg. It provides stable welding parameters for working with the following methods: GMAW (MIG/MAG), SMAW (MMA - shielded metal arc welding), FCAW-G, FCAW-S (flux-cored wire welding), and GTAW (Lift TIG). For each of these processes, the machine allows operation with a maximum current of 420A at a 100% duty cycle. A distinguishing feature of the Speedtec 400SP welder is its air gouging function (CAG) in conjunction with the COOLARC® 60 cooler, as well as its capability for brazing.

EFFICIENCY AND SAFETY

The device, with its reinforced construction from Lincoln Electric, is ready for the toughest working conditions. It is characterized by high efficiency and reliability, and thanks to optimized ergonomics and a professionally designed construction, it ensures continuous operation even in the most demanding production and environmental conditions. The Speedtec 400SP stands out for its exceptional resistance, confirmed by numerous tests, including TRUE HD, CRASH TEST, ELECTROMAGNETIC COMPATIBILITY (EMC) TEST, thermal test confirming uninterrupted operation for 2 hours at +40°C and 55% humidity, and dust test indicating continuous operation for 4 hours in a dust chamber.

The Speedtec 400SP welder has an IP23 protection rating, which confirms protection against solid objects with a diameter of 12.5 mm or greater and protection and stability of the equipment’s operation when positioned at an angle up to 60° from the vertical on each side. The tunnel-like construction of the cooling system prevents dust and dirt from entering the electronic systems. The protected electronic systems guarantee durability and safety.

APPLICATION IN VARIOUS INDUSTRIAL SECTORS

The Speedtec 400SP is excellently suited for heavy industry, construction, and shipbuilding. Thanks to a rich range of synergic lines and the high-quality short-circuit arc SpeedShort Arc™ which features faster wire feeding speed. High PenetrationSpeed™ provides deeper penetration. SoftSilencePulse™ reduces noise levels and ensures better wetting when welding stainless steel. MECHAPULSE™ guarantees high-quality welds with a regular pattern similar to fish scales. The software also includes Production Monitoring (Checkpoint). The Speedtec 400SP further ensures precise wire feeding and, with the Advance panel, enables brazing. The Lincoln Electric semi-automatic welder can be used in light production as well as for all machine repairs and installations, as it provides stable welding parameters for carbon and high-alloy steels, maintaining efficiency above 85%. The device is adapted for use with generator sets and is equipped with long intermediate cables, making it suitable for fieldwork. The Speedtec 400SP is also ideal for those starting their welding journey, as it features a learning-supporting ARCFX panel.

DEVICE CONSTRUCTION

The Speedtec 400SP welder is built on modern inverter technology, which is exceptionally environmentally friendly, providing energy savings (standby/shutdown function). It combines modularity and ease of use while ensuring optimal welding performance. This technology also contributes to faster control of the welding arc compared to analog power sources. Thanks to the machine's compact construction, easy transportation is possible.

4-WHEEL TROLLEY

The four-wheel trolley dedicated to the Speedtec 400SP features a Heavy Duty chassis that ensures stable machine operation, even on surfaces inclined up to 15°. Large wheels facilitate maneuvering and overcoming obstacles such as cables or thresholds. The metal construction, characterized by exceptional stability, makes the trolley even more resistant to mechanical damage. The rotating wire feeder and rotating support allow the feeder to be positioned in any direction.

The trolley has a lowered shelf for the gas cylinder, which is quickly and easily mounted with a chain. For even greater work comfort, the user has access to 4 transport handles, which facilitate easy handling while wearing gloves and safe relocation of the device. Additionally, the trolley has a place for the welding torch and a hanger for the combined cable, particularly useful for long cables. The trolley is equipped with rubber protectors to protect legs and chains to ensure efficient securing of the equipment.

COOLARC COOLER

The COOLARC 60 cooler is fully controlled by the power source. It features high cooling efficiency (1.1 kW at 25°C) and has a tank capacity of 4.5 liters. An efficient pump motor provides additional cooling. The internal LED lighting ensures good visibility of the coolant level. The cooler can operate in one of three modes: AUTO/ON/OFF. It is equipped with a flow sensor, which ensures safe operation of the welding torch. These sensors reduce energy consumption and extend the device's lifespan. The device has an IP23 protection rating.

WIRE FEEDERS

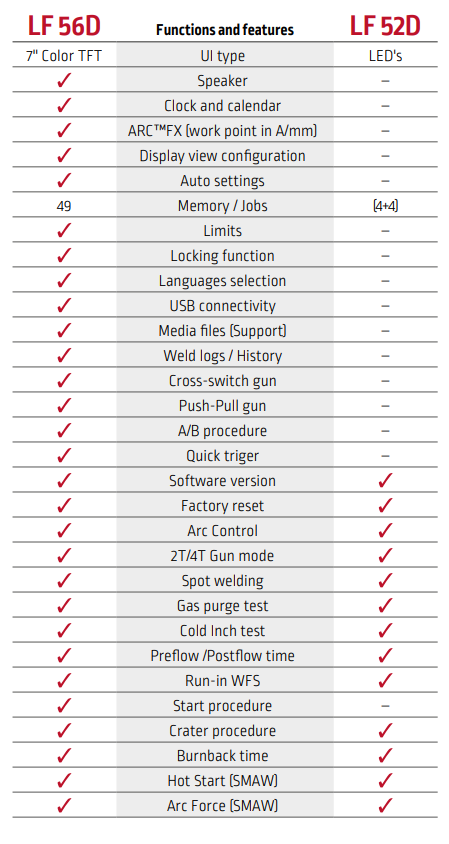

The Speedtec 400SP device allows for the connection of a standard wire feeder - LF52D, which is intended for basic applications, or an advanced feeder - LF56D, designed for the most demanding welding tasks.

In the standard version of the LF52D wire feeder, a wide range of synergic programs is available, allowing simple and precise control of welding parameters to achieve the best results. The control panel on the LF52D wire feeder is highly intuitive and very easy to use, requiring no extensive training. It allows for straightforward navigation in the menu using buttons, providing direct access to commonly used welding parameters such as: wire feed speed (Run-in), arc dynamics - Arc control (inductance), welding torch mode (2-tact/4-tact), and wire burning time to prevent sticking the wire to the weld pool.

Below is a graphic illustrating the interface of the Standard version:

1) Analog display: View of the set welding parameters.

2) Left knob: Setting the parameter value in the upper left corner of the display.

3) Right knob: Setting the parameter value in the upper right corner of the display.

4) Right button: Quick access to the most commonly used welding parameters (Arc control / 2/4T / Run-in / Burn-back)

5) Left button: Selection of the welding process (MIG Manual / FCW Manual / STICK mode) and selection of shielding gas (MIX / CO2 / Ar).

6) Thermal protection indicator: Indicates the thermal overload status of the power source or insufficient cooling. 7) Device status indicator: Indicates system errors. During proper operation, the indicator light is continuously green. 8) Wire feed speed indicator.

9) Current intensity indicator.

10) Voltage indicator.

11) Selected welding method indicator (MIG Manual / FCW Manual / STICK mode)

12) Selected welding parameters indicator (Arc control / 2/4T / Run-in / Burn-back).

The wire feeders LF52D and LF56D offered by Lincoln Electric are equipped with the latest technology and a precise feeding mechanism consisting of 4 large diameter drive rolls (37 mm), ensuring reliable wire feeding regardless of the type of wire. The Speedtec 400SP power source comes factory-equipped with wire rolls for 1.0 mm and 1.2 mm diameter wire, suitable for low-alloy and stainless steel. The aluminum construction of the feeder housings significantly enhances their durability, and the new locking mechanism allows for simple replacement of rolls and guides without the need for tools. Thanks to the use of a rotating support, the wire feeders can be rotated and positioned in any orientation.

Below is a comparison of the features and functions of both feeders:

The SPEEDTEC® 400SP devices come with a 3-year warranty and are manufactured in Poland. Due to the high duty cycle, SPEEDTEC® 400SP semi-automatics are sold with the K14298-1 chassis and COOLARC® 60 cooler, which is essential for optimal cooling of the device.

The set includes:

- SPEEDTEC 400SP welding semi-automatic K14258-1

- Wire feeder: LF-52D STANDARD K14335-1

- COOLARC-60 cooler K14297-1

- Chassis K14298-1

- Combined cable 5m K14199-PGW-5M

- Weldline LGS3 505 W 5m welding torch W10430-505-5M

- Weldline Freezcool 9.6L coolant W000010167

Are you interested in welding equipment? Check out all our MIG/MAG welders!

| Wire feeder: | LF 52D STANDARD |

| Set: | YES |

| Cable length:: | 5 m |