The latest semi-automatic welder POWERTEC® I350S from Lincoln Electric is an extremely durable and efficient device weighing 68 kg and measuring 932 mm x 560 mm x 925 mm, which allows welding using GMAW (MIG/MAG), FCAW (cored wire welding) and SMAW (MMA-coated electrode welding). It allows work in the current range of 20-350A and guarantees stable output parameters:

SAFETY, PERFORMANCE, DURABILITY FOR VARIOUS INDUSTRIES

The device is adapted to work in the harshest environments, and optimized ergonomics and a specially designed structure, the resistance of which is confirmed by, among others, the following tests: TRUE HD, CRASH TEST, ELECTROMAGNETIC COMPATIBILITY TEST (EMC), ensure the continuity of equipment operation, even in the most demanding production and environmental conditions. The machine has IP23 protection and secured electronic systems, which additionally guarantees its durability and safety. The device is an excellent solution for applications in heavy industry, construction, shipbuilding, transport and offshore. Its design is based on modern and environmentally friendly inverter technology, which combines modularity and ease of use, and also ensures optimal welding efficiency and energy savings, including automatic saving modes (standby/shutdown function). This technology also provides much faster control of the welding arc than in the case of analog power sources. The device is adapted to work with generators and has a compact design, which makes it easy to transport.

MACHINE CONSTRUCTION

The Heavy Duty chassis used in the POWERTEC® I350S power source makes the machine exceptionally durable and ensures stable operation even with surface inclinations of up to 15°, and large wheels make it easy to overcome obstacles such as cables or thresholds. The extremely stable, metal construction makes the welder above average resistant to mechanical damage, while the Heavy-duty protective hose, cables with strain reliefs at both ends and armored plugs guarantee a solid connection, even with a wide range of lengths (up to 30 m), regardless of the type of cooling (liquid or air).

The POWERTEC® I350S device is also equipped with a practical handle, ensuring easy grip with gloves and safe movement of the device, as well as rubber protectors, protecting the legs. For even greater comfort of work, the user also has a handy shelf for a gas cylinder, the assembly of which is extremely quick and easy. Two additional chains ensure its efficient and easy securing. Inside the welder there is also an illuminated and lockable compartment for storing accessories such as a handle, rollers, gloves or current tips.

WIRE FEEDERS

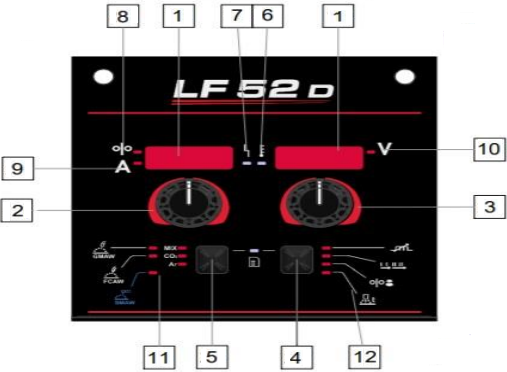

POWERTEC® i350S allows you to connect one of the digital wire feeders: the standard LF52D, which is dedicated to basic applications or the advanced LF56D, intended for the most demanding users.

The LF56D wire feeder is equipped with a 7-inch TFT display, which shows welding process parameters and a simple and intuitive control panel, which ensures uncomplicated and convenient operation, even when wearing welding gloves. The interface is available in multiple languages, including English, German, French, Polish, Spanish, Italian, Russian, etc., and key commands are symbolized by graphic icons. The advanced panel also provides the user with two control knobs and one button for easy menu navigation, and the ARCFX™ function allows for visualization of the connector and parameters. With the LF-56D wire feeder, the set supports MIG processes, thanks to a wide range of synergistic lines, which include: programs for steel, stainless steel, aluminum and cored wires. Available functions include: Lock functions, Parameter limits, Memory and Job modes, which can be password protected. The feeder is additionally equipped with a USB port, which allows for quick uploading of updates. The LF56D wire feeder also allows for selecting programs from the welding torch, which further improves work comfort.

The Advanced version interface is presented below:

1. Analog display: View the values of the set welding parameters,

2. Left knob: Setting the parameter value in the upper left corner of the display,

3. Right knob: Setting the parameter value in the upper right corner of the display,

4. Right button: Quick access to the most frequently used welding parameters (Arc control/2/4T/ Run-in/ Wire burn)

5. Left button: Selecting the welding process (MIG Manual/ FCW Manual, STICK mode) and selecting the shielding gas (MIX/CO2/Ar)

6. Thermal protection indicator: indicates a thermal overload condition of the power source or insufficient cooling

7. Device status indicator: indicates system errors. During proper operation, the indicator light stays green,

8. Wire feed speed indicator

9. Current indicator

10. Electric voltage indicator

11. Indicator of the selected welding method (MIG Manual/ FCW Manual/ STICK mode)

Both wire feeders (LF52D and LF56D) offered by Lincoln Electric are equipped with the latest wire feeding technology. The solid and precise feeding mechanism, consisting of 4 large diameter drive rolls (37 mm), guarantees solid wire feeding, regardless of its type. The device is equipped with factory-installed rollers for 1.0 mm and 1.2 mm wire made of low-alloy and stainless steel. The new locking mechanism enables easy replacement of rollers and guides, without the use of tools. The housing of the wire guides is made of aluminum, which significantly increases their durability, and the use of a rotating bracket allows the wire feeders to be rotated and set in any position.

Below is a comparison of the features and functions of both feeders:

POWERTEC® I350S devices are manufactured in Poland and have a 3-year warranty. Like other power sources of this series, they have the option of liquid cooling by connecting the optional COOLARC® 26 cooler, which is also available in our offer.

The set includes:

● POWERTEC i350S semi-automatic welder K14183-1

● LF-52D STANDARD wire feeder K14335-1

● Interconnection cable, 15m K14198-PG-15M

● Hanger for rolled combined cable K14201-1

● Weldline LGS3 360 G 5m welding torch W10430-36-5M

Are you interested in welding equipment? Be sure to check out all our mig mag welders!

| Wire feeder: | LF 52D STANDARD |

| Set: | NO |

| Cable length:: | 15 m |