The Fronius Ignis 180 is a new generation single-phase electrode welder with a power of 180A for the MMA method and 220A for the TIG method. The device has an extended range of functions, ensuring ideal welding results. Modern PFC (Power Factor Correction) technology is responsible for power factor control, ensuring optimal energy consumption, which reduces the number of interferences that are given to the power grid and increases savings. The product also allows for work without voltage spikes when using long cables (up to 100 meters).

The Fronius Ignis 180 welder enables manual welding with a coated electrode with a diameter of no more than 4 mm. The inverter also has an additional mode (CEL), designed for work with cellulose electrodes. It guarantees a stable arc and is particularly useful when welding in difficult positions, e.g. from top to bottom, without causing creep. The digital controller is responsible for adjusting the welding source characteristics to the welding electrode, which ensures a small amount of spatter during work and optimal electrode ignition at a low short-circuit current. Voltage reserves are a guarantee of high welding arc stability. Regardless of the selected welding method, the results are always excellent.

Ignis 180 Welder - Features:

HOT START function, which helps to ignite the electrode by increasing the current intensity for 0.1 to 1.5 seconds. It also ensures better fusion of the base material at the initial stage, which reduces the number of cold spots. The function also protects against slag inclusion, causing it to easily come off the weld. Hot start is used for electrodes with a diameter of 3.2 and 4 mm.

The SOFT-START function helps to reduce the welding current in the initial phase of operation, thus ensuring ideal arc stability. Soft-Start is used for smaller basic and high-alloy electrodes, e.g. for stainless steel. This function reduces the formation of pinholes and reduces the likelihood of electrode sticking. SOFT-START is set in the range of 30%-99%, and Hot Start 101%-200%. The inverter also has an

ANTI-STICK function, which, when the electrode short-circuits, causes the welding current value to decrease, and after 1.5 seconds, the welding arc is extinguished. Thanks to this function, the electrode is easier to detach from the welded element, and the welding handle is also protected against possible damage.

The START RAMP function, which is equipped with the device, causes the power value to increase in a ramp manner - when the arc is struck, the power is 5A, then 35A, after which it switches to Hot Start or Soft Start, according to the previous settings. This process takes 100 milliseconds and is imperceptible. The start ramp function contributes to a gentle arc ignition and prevents the electrode from sticking.

The Fronius TransPocket 180 also has an arc interruption function "U CUT OFF", which is used to define at what arc length the welding process should be ended. The welding voltage increases with the length of the welding arc, and when the set voltage value is reached, the arc extinguishes.

It is also possible to set the DYNAMICS parameter in the device, which allows you to achieve optimal welding results. A lower dynamics value results in a smaller penetration depth and a softer arc, while increasing this parameter allows for greater penetration and a more focused arc. Dynamics affects the short-term increase in current intensity in the event of a short circuit or at the moment of droplet transfer, which creates a stable welding arc. This action prevents the weld pool from solidifying and prevents the arc from shorting for a longer period of time. This protects against the consumable electrode becoming immobilized.

The Fronius Ignis 180 welder also offers a PULSED ARC welding function, which can be set in a frequency range from 0.5 to 100 Hz. This method is used for welding steel pipes, which are performed in forced positions, e.g. vertical or eaves welds. It is also used for welding thin materials. During pulse welding, heat energy is introduced into the weld in pulses and is cooled between successive pulses. This helps to obtain the right shape of the weld and prevents the appearance of weld spatter. This type of welding produces two types of current: a basic current (I-G), which maintains the welding arc, and a pulsed current (I-P), which transfers metal to the weld pool without causing spatter or short circuits.

Ignis 180 enables TIG Lift welding (strike ignition) using a traditional welding torch with a valve in the handle. After selecting the "TIG welding" option in the device menu, set the welding current and then place the gas nozzle on the ignition point. It is recommended that the distance between the tungsten electrode and the welded element is about 2-3 mm (illustration 1). Then, open the shut-off valve to begin the flow of shielding gas and gradually level the welding torch until the electrode touches the workpiece (illustration 2). The welding arc is ignited (illustration 3) after lifting the welding torch and tilting it to the normal position, as shown in the graphic below:

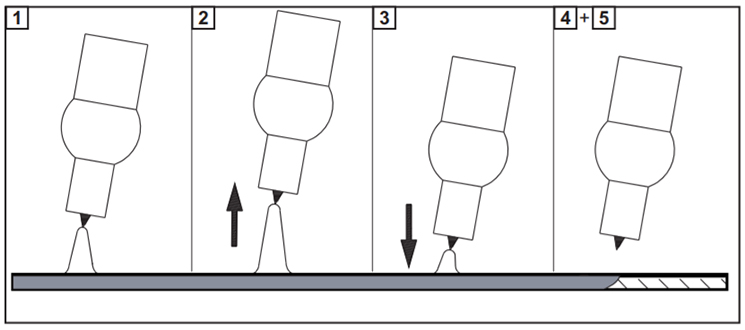

The Fronius Ignis 180 inverter also has a TIG COMFORT STOP function, which allows for a gentle end to the welding process and prevents burns and discoloration in the material. During the welding process, the welding torch should be raised (illustration 2), which extends the arc, and then lowered back (illustration 3), which causes the welding arc to shorten and slowly extinguish due to the linear decrease in current value (Down Slope) (illustration 4). After the welding process is finished, wait until the gas flows out and then move the torch away from the welded material (illustration 5). It is important to close the valve in the handle to turn off the gas flow. The use of the TIG Comfort Stop function and the principle of its operation are shown in the illustration below:

Parameters in Fronius Ignis 180 for MMA welding:

![]() - Allows you to set the duration of the starting current for the Soft-Start and HotStart functions in the range of 0.1-1.5 seconds.

- Allows you to set the duration of the starting current for the Soft-Start and HotStart functions in the range of 0.1-1.5 seconds.

- The AntiStick function causes the welding arc to extinguish only after 1.5 seconds when the electrode sticks to the material.

- The AntiStick function causes the welding arc to extinguish only after 1.5 seconds when the electrode sticks to the material.

![]() - Parameter responsible for activating and deactivating the launch ramp.

- Parameter responsible for activating and deactivating the launch ramp.

![]() - Welding arc interruption voltage (U cut off) adjustable in the range of 25-90 V.

- Welding arc interruption voltage (U cut off) adjustable in the range of 25-90 V.

![]() - Factory Default (FACtory). This parameter allows you to restore the device to its factory settings.

- Factory Default (FACtory). This parameter allows you to restore the device to its factory settings.

- Setup menu, level 2 - Parameter for setting general parameters.

- Setup menu, level 2 - Parameter for setting general parameters.

Parameters in Fronius Ignis 180 for TIG welding:

![]() - Comfort Stop Sensitivity. The parameter is adjustable in the range of 0.5-2.5 V, allowing for a gentle end to the welding process.

- Comfort Stop Sensitivity. The parameter is adjustable in the range of 0.5-2.5 V, allowing for a gentle end to the welding process.

![]() - Welding arc cut off voltage (U cut off) adjustable in the range of 12-22 V. It is used to set the arc length at which the welding process is completed.

- Welding arc cut off voltage (U cut off) adjustable in the range of 12-22 V. It is used to set the arc length at which the welding process is completed.

![]() - FACtory Factory Settings. This parameter allows you to reset the device to its factory settings.

- FACtory Factory Settings. This parameter allows you to reset the device to its factory settings.

![]() - Setup menu, level 2 - used to set general parameters.

- Setup menu, level 2 - used to set general parameters.

Parameters in the Fronius Ignis 180 in the setup menu level 2:

- Information about the full version number of the current software, which is divided into several indications on the display.

- Information about the full version number of the current software, which is divided into several indications on the display.

- Automatic shutdown timeShut down. Setting this function between 5-60 minutes turns the device off.

- Automatic shutdown timeShut down. Setting this function between 5-60 minutes turns the device off.

- Security. This function is used to set and display security.

- Security. This function is used to set and display security.

![]() - System on time. A parameter that allows you to display the operating time counted from the moment the device is turned on.

- System on time. A parameter that allows you to display the operating time counted from the moment the device is turned on.

- Welding time (System Active time). A parameter showing only the welding time.

- Welding time (System Active time). A parameter showing only the welding time.

The set includes:

- Ignis 180A welding machine

- Electrode holder 25mm² 4m

- Ground cable 25mm² 4m

Check out the other MMA inverter welders in our offer!

| Duty cycle 40%: | 180 A |

| Duty cycle 60%: | 160 A |

| Duty cycle 100%: | 120 A |

| Operating voltage: | 20,4V - 27,2V |

| Open-circuit voltage: | 101,0 V |

| Mains frequency: | 50-60Hz |

| Mains voltage: | 230V |

| Mains fuse: | 16A |

| Dimension / b : | 160 mm |

| Dimension / l: | 435 mm |

| Weight: | 8,8 kg |

| Degree of protection: | IP23 |