OP 121TT is a fully basic agglomerated submerged-arc welding flux that is widely used for the welding of structural and fine grained low alloy steels requiring high integrity welds with low temperature impact and CTOD fracture toughness properties.

OP 121TT flux, in combination with a range of Oerlikon submerged-arc wires, in particular with OE-SD3, is established for the welding of offshore structures such as oil platform jackets, piles, decks and modules giving a high level of consistency and mechanical property performance. The flux is widely used for the welding of thick section components in the offshore, nuclear and pressure vessel industries. The flux exhibits a lowhydrogen content in the as manufactured condition and gives a high resistance to moisture pick up during exposure under workshop conditions. The flux promotes a very stable arc characteristic during use with excellent slag detachment. The weld is of a uniform even profile with regular fine ripple formation and smooth toe blending.

OP 121TT flux is suitable for use with DC+ or AC and is ideal for single wire, twin wire, tandem arc [DC+/AC] and other multi-arc systems using up to 1000A with single wire welding. Grain size according to EN 760: 2-20.

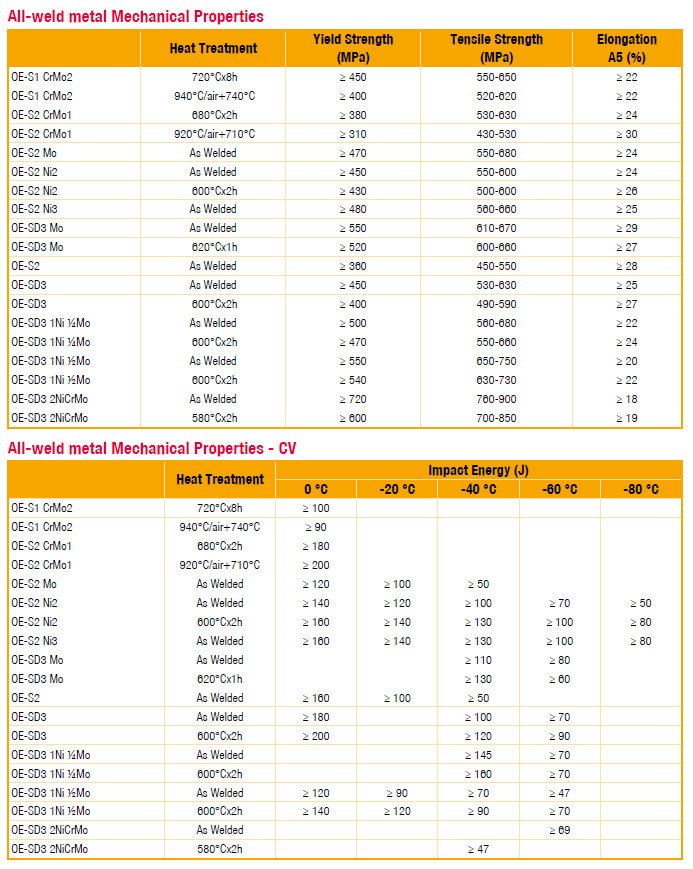

Matrials:

- OE-S2 Mo ASME: X60, X65, ASTM A355 Gr. P1; A182M Gr. F1 EN: 16Mo3, S(P)355-S(P)460, L245-L450

- OE-S2 CrMo1 ASME: A199 i A200 gatunki T11, A213 gatunki T11, T12 EN: 13CrMo4-5, 13CrMoSi5-5 OE-S2 Ni2 EN: 11MnNi5-3, 15NiMn5-3 OE-S2 Ni3 ASME: ASTM A333 gatunki 3, ASTM A334 gatunki 3; A352LC3; ASTM A203 D, E EN: 12Ni14, S(P)275-S(P)460

- OE-S2 ASME: ASTM A131 gatunki A, B, D, DS; A253 wszystkie gatunki; A529 gatunki 42, 50; A570 wszystkie gatunki; A572 gatunki 42, 50; A709 gatunki 36, 50

- EN: S(P)235-S(P)355; L245-L360

- OE-SD3 ASME: A516 wszystkie gatunki EN: S(P)235-S(P)420

- OE-SD3 1Ni ¼Mo ASME: ASTM A131 AH40, DH40, EH40, X65, X70 EN: S(P)275-S(P)460

- OE-SD3 1Ni ½Mo ASME: X70, X80, N-A-XTRA 55, HY80, QIN EN: S(P)420-S(P)500; L245-L485; 20MnMoNi5-5, 15NiCuMoNb5