OP 139 is an agglomerated aluminate-basic type flux which has been designed for use with the high deposition rate submerged arc processes. Therefore OP 139 is perfectly suited for single or multi-layer welding in twin-wire, tandem or multi-wire processes both for longitudinal and circumferential seams.

Even at high speeds the weld metal shows good wetting properties and smooth and straight weld toes. The slag detaches very easily even in narrow joint configurations and fillet welds.

The agglomerated welding flux OP 139 can be used for all structural, boiler and pipe steels and for fine-grained structural steels. There is a low silicon and a significant manganese pick-up.

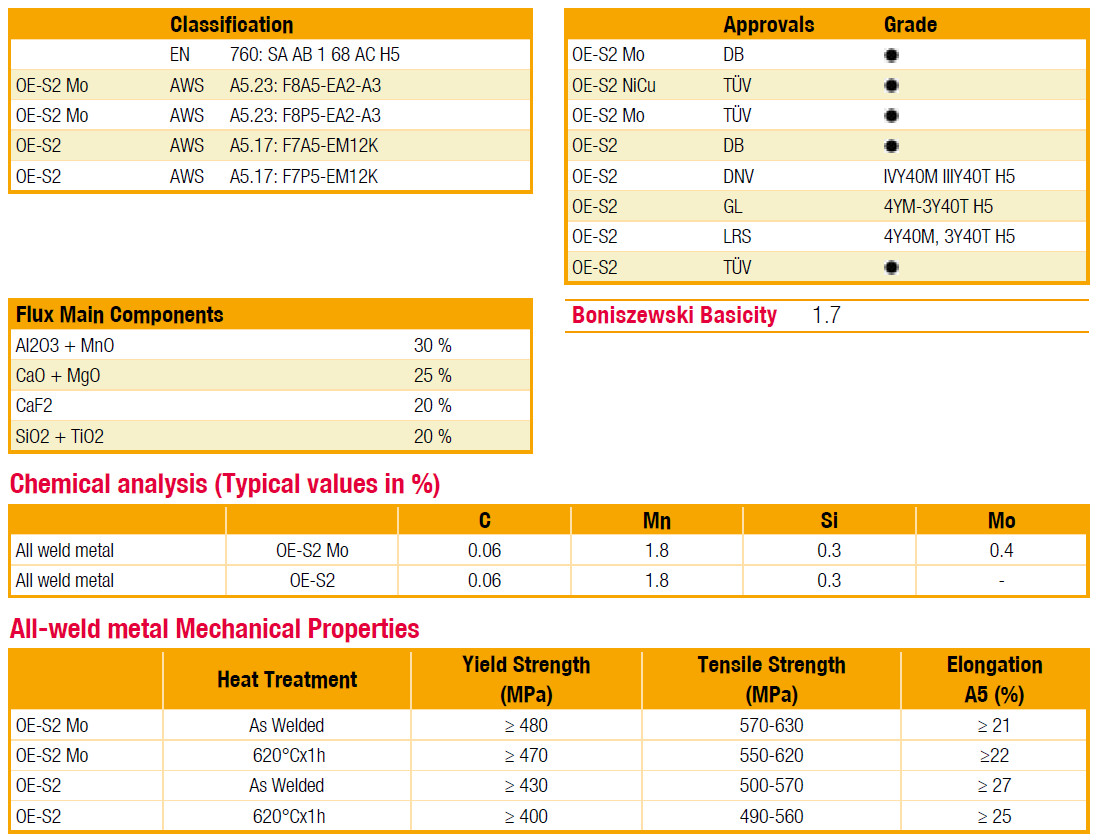

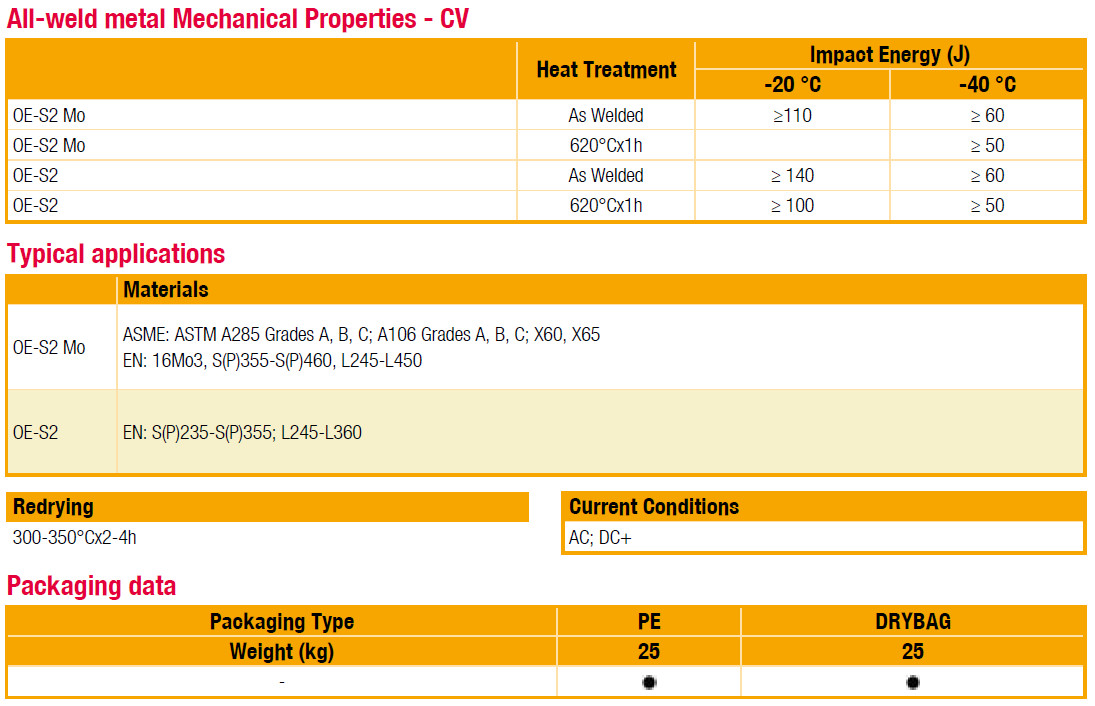

Preferably, OP 139 is used in combination with wire electrode OE-S2 in multi-layer welds and in combination with wire electrode OE-S2Mo when welding from both sides in one pass.

Damp flux should be re-dried at 300-350°C.

Grain size according to EN 760: 2-20.

Materials

OE-S2 Mo ASME: ASTM A285 gatunki A, B, C; A106 gatunki A, B, C; X60, X65

EN: 16Mo3, S(P)355-S(P)460, L245-L450

OE-S2 EN: S(P)235-S(P)355; L245-L36